Fiberglass purlins stand as indispensable structural elements in building construction, providing crucial support for roofs and efficiently transferring loads to the main framework. Crafted from fiberglass reinforced plastic (FRP), these purlins boast exceptional strength, durability, and corrosion resistance, making them a preferred choice for diverse construction endeavors.

Crafting Excellence:

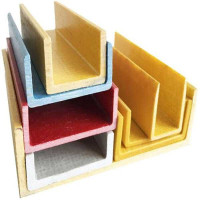

Manufactured through the pultrusion process, fiberglass purlins undergo a meticulous journey. Fiberglass strands are drawn through a resin bath and then a heated die, resulting in purlins that are robust, lightweight, and capable of withstanding harsh environmental conditions with ease.

Versatile Applications:

Fiberglass purlins offer versatility in application, finding their place in various settings:

- Agricultural Settings: Widely employed in livestock shelters, storage buildings, and greenhouses, fiberglass purlins exhibit resilience against moisture, chemicals, and UV rays. Their durability ensures longevity, even in environments where traditional materials falter.

- Industrial and Commercial Buildings: Serving as dependable support for roofs, canopies, and awnings, fiberglass purlins shine in industrial and commercial settings. Their high strength-to-weight ratio streamlines installation and minimizes the overall load on the building structure.

Market Dynamics:

The fiberglass purlin market is witnessing robust growth, fueled by several factors:

- Construction Industry Boom: Rapid urbanization and infrastructure development globally are driving demand for durable, lightweight, and corrosion-resistant building materials like fiberglass purlins. Their superior performance and versatility make them a preferred choice across diverse industries.

- Agricultural Sector Demand: In agricultural applications such as livestock shelters, barns, and greenhouses, fiberglass purlins are in high demand due to their resilience against harsh environmental conditions. This sector values their moisture, chemical, and UV resistance.

- Industrial Sector Reliance: Warehouses, factories, and manufacturing facilities rely on fiberglass purlins for roof support. Their durability and corrosion resistance make them ideal for structures exposed to harsh chemicals, temperature fluctuations, and corrosive gases.

- Commercial Sector Adoption: Retail buildings, office complexes, and recreational facilities increasingly turn to fiberglass purlins for various applications. Their lightweight nature facilitates easier installation and reduces the overall load on the building structure, contributing to cost savings and efficiency.

As the construction industry prioritizes sustainability and energy efficiency, fiberglass purlins emerge as an environmentally friendly alternative to traditional materials. Their long lifespan, low maintenance requirements, and recyclability position them favorably for green building projects.

In summary, the fiberglass purlin market is poised for sustained growth as industries seek durable, lightweight, and sustainable solutions for their construction needs. With continuous innovations in manufacturing techniques and product design, fiberglass purlins are set to play a pivotal role in shaping the future of modern construction endeavors.