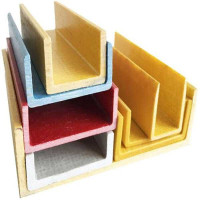

Fiberglass beams represent essential structural elements crafted from fiberglass reinforced plastic (FRP), serving a multitude of purposes across construction and industrial landscapes. Engineered to deliver robustness and longevity, these beams stand out for their lightweight composition and corrosion-resistant properties.

Manufacturing Marvels:

The crafting process of Fiberglass Beam incorporates cutting-edge materials and methodologies to yield a sturdy, lightweight, and enduring structural asset. Employing pultrusion, Fiberglass Beam, or Fiberglass I-Beam, amalgamates glass fibers and resin into a cohesive entity.

Pultrusion, a continuous manufacturing technique, entails drawing fibers through a resin bath, ensuring complete saturation. Subsequently, these fibers traverse a heated die, assuming the desired profile, such as an I-beam, as the die cures the resin, bestowing rigidity and durability.

The materials meticulously selected for the Fiberglass Beam manufacturing process epitomize strength, durability, and compatibility with pultrusion. Derived from silica sand, limestone, and other minerals, the glass fibers intertwine to form a fabric or mat, fortifying the beam. Meanwhile, thermosetting plastics like polyester or epoxy resin, adept at bonding with glass fibers, furnish the requisite strength and endurance.

The fusion of advanced materials and techniques underpins Fiberglass Beam's versatility and reliability. Whether in construction, marine ventures, or industrial domains, Fiberglass Beam proffers a resilient and cost-efficient solution for diverse projects.

Versatile Applications:

Fiberglass beams find extensive utility in construction realms, comprising building frames, bridges, and support structures. Similarly, they feature prominently in industrial milieus, supporting platforms, walkways, and structural beams.

Advantages:

- Foremost among the benefits of fiberglass beams is their impressive strength-to-weight ratio. This characteristic renders them lighter and more manageable compared to traditional materials like steel or wood, all the while ensuring requisite structural integrity.

- Moreover, fiberglass beams boast resilience against corrosion, chemicals, and UV rays, rendering them apt for deployment in challenging environments. Their non-conductive nature further enhances their appeal, particularly in electrical applications.

In summation, fiberglass beams emerge as a versatile and robust solution catering to a spectrum of structural needs. Their blend of strength, lightweight construction, and corrosion resistance positions them as a preferred choice across diverse industries.