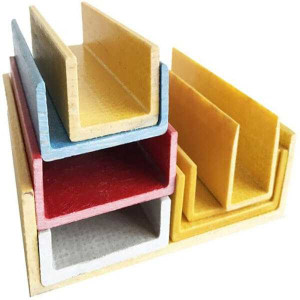

Fiberglass channels represent essential structural profiles crafted from fiberglass reinforced plastic (FRP), finding myriad applications across diverse industries. Engineered to deliver strength, durability, and corrosion resistance, these channels embody a lightweight and cost-effective solution.

Crafting Excellence:

The manufacturing process of fiberglass channels primarily revolves around pultrusion, a technique that involves pulling fiberglass strands through a resin bath and then through a heated die to shape the profile. This meticulous process yields a robust and uniform channel that withstands bending, twisting, and corrosion with aplomb.

Versatile Applications:

Fiberglass Channel, also known as Fiberglass C-Channel, emerges as a versatile structural component catering to a plethora of applications across industries. Renowned for its durability and lightweight construction, it finds its niche in demanding environments.

Diverse Applications:

Fiberglass Channel finds extensive utility across various sectors:

- Construction Industry: In construction, fiberglass channels serve as stalwart structural supports, framing elements, and reinforcement components. Their exceptional strength-to-weight ratio renders them invaluable for weight-sensitive applications like bridges, building frames, and support structures.

- Marine Industry: Fiberglass Channel finds a natural fit in the marine industry, where it is a staple for boat building and marine infrastructure. Its resilience against corrosion and water damage ensures longevity in marine environments where traditional materials falter.

- Industrial Settings: Industrial environments benefit from the versatility of Fiberglass Channel, which finds use in platforms, walkways, and support beams. Its non-conductive nature renders it ideal for electrical applications, while its durability guarantees sustained performance in harsh industrial conditions.

Assured Benefits:

Fiberglass channels offer an array of advantages:

- High Strength-to-Weight Ratio: The notable strength-to-weight ratio of fiberglass channels facilitates ease of handling, surpassing traditional materials like steel or wood while maintaining structural integrity.

- Corrosion Resistance: Resistant to corrosion, chemicals, and UV rays, fiberglass channels excel in harsh environments, ensuring longevity and reliability.

- Non-Conductive Properties: The non-conductive nature of fiberglass channels enhances their suitability for electrical applications, further augmenting their utility across industries.

In essence, Fiberglass Channel stands as a testament to versatility and durability, addressing diverse project needs with unwavering reliability and performance.