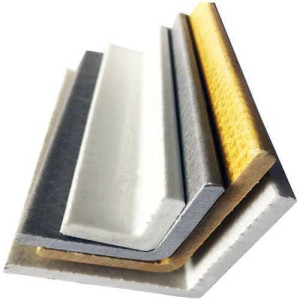

Welcome to our ultimate guide to Fiberglass Angle, a remarkable building material that's revolutionizing various industries. Fiberglass Angle, also referred to as Fiberglass Angle Iron, stands as a fortified plastic material crafted from a fusion of glass fibers submerged in a resilient resin matrix. This ingenious blend yields a lightweight yet extraordinarily robust substance resistant to corrosion, weathering, and chemical exposure.

Materials Involved in Production:

In crafting Fiberglass Angle, several pivotal materials come together, ensuring its robustness, endurance, and adaptability. Typically, Fiberglass Angle is concocted from a blend of glass fibers, resin, and assorted additives for heightened performance.

- Glass Fibers: Acting as the backbone, glass fibers exhibit strength, flexibility, and resistance to both heat and corrosion. Sourced from silica sand, limestone, and other minerals, these fibers undergo melting and drawing processes, eventually intertwining to form a fabric or mat, serving as the reinforcement in Fiberglass Angle.

- Resin: The resin employed in Fiberglass Angle is commonly a thermosetting plastic, such as polyester or epoxy resin. Mixed with a catalyst, this resin is applied onto the glass fibers, where it undergoes curing and hardening, fostering a robust bond. Beyond binding the fibers, the resin also safeguards against moisture, chemicals, and environmental elements.

- Additional Enhancements: To further augment its properties, Fiberglass Angle may incorporate additional materials. Fillers like calcium carbonate or alumina trihydrate may bolster fire resistance, while pigments infuse color into the material.

In essence, meticulous material selection ensures that Fiberglass Angle upholds the highest benchmarks of quality and performance. Whether for construction, marine ventures, or industrial pursuits, rest assured, Fiberglass Angle is forged from top-tier materials to ensure durability and longevity.

Applications:

Fiberglass Angle finds widespread utilization across construction, marine, and industrial domains, owing to its remarkable strength-to-weight ratio and resilience to environmental stressors. Its non-conductive nature renders it ideal for electrical tasks, while its low thermal conductivity suits settings necessitating precise temperature control.

Advantages:

The versatility of Fiberglass Angle stands as its hallmark advantage. Easily cut, drilled, and molded to bespoke specifications, it accommodates a myriad of structural and non-structural tasks with ease. Whether fortifying corners, fashioning supports for shelving, or reinforcing composite structures, Fiberglass Angle delivers a dependable and economical solution.

In sum, Fiberglass Angle emerges as a versatile ally across diverse industries, embodying strength, durability, and adaptability. Its extensive applications and inherent advantages position it as a staple choice for modern construction and industrial endeavors.