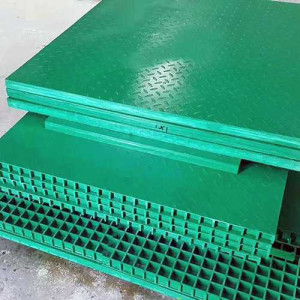

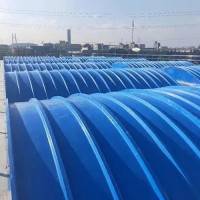

Looking for a robust safety solution with a sleek finish? Covered FRP grating is your answer. Unlike open mesh gratings ( like concave gratings, micro-mesh gratings, etc. ) this fiberglass reinforced plastic grating boasts a solid top surface, offering seamless continuity without gaps between bars. Let's dive into the details:

Manufacturing Process:

- Mold Preparation: Begin with crafting a mold that matches the desired size and shape of the grating panels, usually crafted from metal or fiberglass.

- Fiberglass Reinforcements: Cut fiberglass reinforcements to size, typically continuous strands or woven mats.

- Resin Mixing: Blend a resin mixture with catalysts and additives to achieve desired properties like chemical or fire resistance.

- Layering Process: Strategically lay fiberglass reinforcements in the mold for strength and stiffness.

- Resin Infusion: Pour resin into the mold to saturate reinforcements, ensuring thorough impregnation.

- Curing: Allow resin to cure, forming a solid structure through heat and/or chemical reaction.

- Demolding: Remove cured grating panel from the mold, trim excess material, and inspect for quality.

- Surface Finishing: Further refine the solid top surface through sanding or coating for texture, color, and surface properties.

- Quality Control: Conduct quality checks to ensure panels meet strength, dimension, and surface quality requirements.

- Packaging and Shipping: Prepare finished panels for shipment to customers, ready to be installed in various applications.

Further Process for Solid Covers:

- Preparation of Materials: Select and treat materials like fiberglass, resin, and fillers to remove moisture and impurities.

- Adhesive Coating: Apply resin onto pre-treated glass fiber on the mold, ensuring even mixing with the filler.

- Compression Molding: Subject coated material to heating and pressing to solidify and form.

- Post Treatment: Trim, polish, and clean the formed fiberglass grating cover for a smooth, even surface.

Benefits & Advantages:

- Exceptional Slip Resistance: The solid top surface ensures stable footing, ideal for slippery environments.

- Protection Against Falling Objects: Prevents small objects from passing through, reducing risk of injury or damage.

- Durability: Resistant to corrosion, chemicals, and UV rays, ensuring longevity in harsh conditions.

- Aesthetic Appeal: Customizable in various colors and textures to complement surrounding design.

In summary, covered FRP grating offers durability, safety, and aesthetic appeal across industrial, commercial, and residential applications. Its solid top surface makes it a preferred choice for those seeking both functionality and style.